- This topic is empty.

-

AuthorPosts

-

2025-03-27 at 4:40 pm #6257

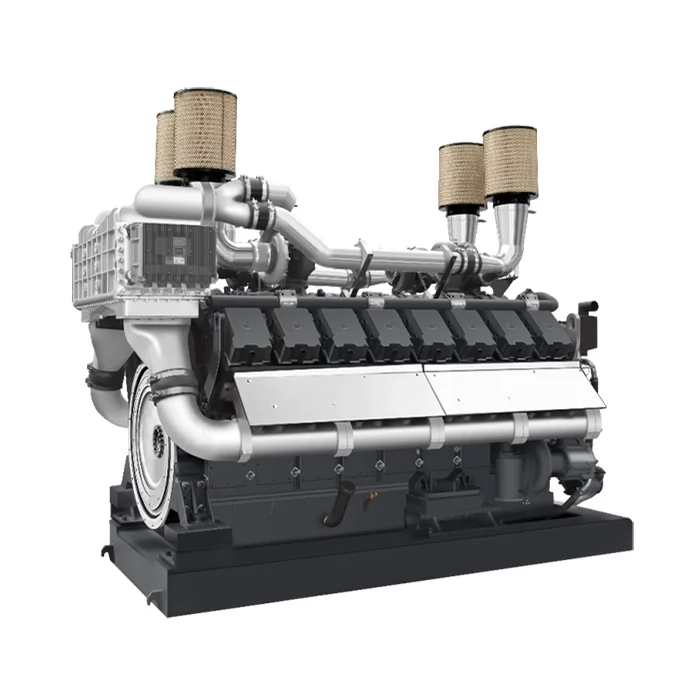

Diesel engines are widely used in various industries for their fuel efficiency, durability, and high power output. However, different engine designs come with unique cooling system configurations that influence performance, maintenance needs, and overall reliability. Among these designs, vertical diesel engines and air-cooled diesel engines stand out due to their distinct cooling mechanisms. While both serve similar functions in providing power, their cooling systems are designed differently, which impacts their applications and suitability for different environments. This article explores the key differences in cooling system design between vertical diesel engines and air-cooled diesel engines, shedding light on their advantages, challenges, and optimal use cases.

Cooling Systems in Diesel Engines

Diesel engines generate significant amounts of heat during operation, which must be dissipated efficiently to prevent overheating and maintain performance. Typically, diesel engines utilize two primary cooling systems:

-

Liquid Cooling System: In this system, coolant (usually a mixture of water and antifreeze) circulates through the engine to absorb heat and is then cooled by a radiator or heat exchanger.

-

Air Cooling System: In this system, the engine relies on air to dissipate heat, with fins and ducts designed to increase surface area and airflow around the engine to aid in cooling.

Both vertical diesel engines and air-cooled diesel engines can use either of these cooling mechanisms, but the way they are implemented and function in these engine types varies significantly.

1. Vertical Diesel Engines: Liquid-Cooled Systems

Vertical diesel engines are characterized by their vertical cylinder configuration, where the engine's components are arranged in a vertical position. Most vertical diesel engines are equipped with liquid cooling systems. Here’s why:

Cooling Design in Vertical Diesel Engines

In vertical diesel engines, the liquid cooling system typically uses a closed-loop coolant system. The coolant circulates through a series of channels within the engine, including the cylinder head and block. A radiator or heat exchanger dissipates the heat absorbed by the coolant, with the liquid coolant being pumped through the engine and cooled before it circulates again.

Advantages of Liquid Cooling in Vertical Diesel Engines:

-

Consistent Temperature Control: Liquid cooling systems are highly effective at maintaining a consistent engine temperature, even under high loads and extended operation.

-

Efficient Heat Dissipation: With the ability to transfer heat more effectively than air, liquid cooling systems can handle the higher thermal loads typically generated by vertical diesel engines, which are often used in heavy-duty applications.

-

Lower Noise and Vibration: Liquid cooling helps dampen the engine's operational noise and vibrations, leading to smoother and quieter performance.

-

Less Heat Radiation to Surrounding Environment: The liquid cooling system keeps excess heat away from the engine components and surrounding areas, which can be crucial in preventing damage to nearby components.

Challenges with Liquid Cooling in Vertical Diesel Engines:

-

Complexity: The liquid cooling system is more complex than air cooling, requiring additional components such as a water pump, thermostat, and radiator.

-

Maintenance: The system needs regular checks and maintenance, including coolant level monitoring and occasional flushing to remove contaminants.

-

Weight: The liquid cooling system adds weight to the engine, which can be a factor to consider in applications where weight is critical.

2. Air-Cooled Diesel Engines: Simpler and More Compact

In contrast to the liquid-cooled vertical diesel engines, air-cooled diesel engines rely on air circulation to cool the engine components. This design is typically found in smaller engines and is more prevalent in applications like portable generators, lawn equipment, and some light vehicles.

Cooling Design in Air-Cooled Diesel Engines

Air-cooled diesel engines feature finned components (like the cylinder head and engine block) that increase the surface area of the engine parts exposed to airflow. As the engine runs, fans or the natural motion of the vehicle direct air over these fins, absorbing the heat and expelling it into the surrounding environment. No liquid coolant is involved, and instead, the engine relies on the ambient air to dissipate the heat.

Advantages of Air-Cooling in Diesel Engines:

-

Simplicity and Compactness: Air-cooled engines have fewer components compared to liquid-cooled systems, making them simpler, lighter, and more compact.

-

Reduced Maintenance: Since there is no coolant to monitor or replace, air-cooled engines require significantly less maintenance than liquid-cooled engines. There are fewer parts that could fail or need regular inspection.

-

Lower Initial Cost: The simplicity of the air-cooling system often results in a lower initial purchase cost for air-cooled diesel engines.

-

Ideal for Smaller Engines: Air-cooled engines are well-suited for smaller, portable machinery that does not require long-term, heavy-duty operation.

Challenges with Air-Cooling in Diesel Engines:

-

Temperature Fluctuations: Air cooling is less effective at managing temperature extremes, particularly in heavy-duty applications. Air-cooled engines may struggle to maintain optimal operating temperatures under continuous high-load conditions.

-

Inefficiency in High Power Demands: Air-cooled systems are generally less efficient at dissipating heat when compared to liquid systems, which can be problematic in engines with high power output or prolonged usage.

-

Environmental Sensitivity: The cooling performance of an air-cooled engine is highly dependent on environmental conditions such as air temperature and humidity. In very hot or still environments, the engine may overheat more easily.

-

Larger Size for Cooling: To compensate for the less efficient heat transfer of air, air-cooled engines often require larger surface areas (i.e., fins) or larger cooling fans, which can increase the size of the engine.

3. Key Differences in Cooling Systems

Feature Vertical Diesel Engine (Liquid Cooled) Air-Cooled Diesel Engine Cooling System Liquid coolant (water/antifreeze mixture) Air and fans Maintenance Requires regular coolant checks and flushing Minimal maintenance (no coolant) Cooling Efficiency Very efficient, consistent temperature control Less efficient, sensitive to ambient temperature Component Complexity More complex with water pump, radiator, etc. Simple design with fewer parts Ideal Applications Heavy-duty, industrial, long-running machines Small, portable, and light-duty machinery Durability High durability under demanding conditions Better for short-duration or light loads 4. Conclusion

Both vertical diesel engines and air-cooled diesel engines have their own unique advantages depending on the specific application. Vertical diesel engines with liquid cooling systems are ideal for heavy-duty, high-performance applications where consistent cooling and long-term reliability are essential. On the other hand, air-cooled diesel engines excel in compact, portable applications where simplicity, low cost, and ease of maintenance are the primary considerations.

Understanding the cooling system design is crucial in selecting the right engine for your needs. For industries requiring high power output and continuous operation, vertical diesel engines with liquid cooling are often the best choice. For lighter, smaller, and more cost-sensitive applications, air-cooled diesel engines may be the optimal solution.

http://www.wandipower.com

Wuxi Power Engineering Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.